| |

|

|

| |

|

Technology |

|

|

|

| |

|

|

| |

ALUBOND U.S.A SOLAR COLLECTOR MIRROR - LIGHT-WEIGHT METALLIC MIRROR |

|

| |

The Alubond Solar Collector Mirror ( ASCM ) is a light weight composite metallic mirror with high total solar reflectance is invented, designed, developed in U.S.A by Mulk Enpar R.E’s Khurram Khan Nawab and patented in U.S.A and Worldwide. ASCM is a result of pioneering research in metal composite technology with a special innovative and patented coating. American Building Technologies Inc (ABTI) brings this innovation to CSP, CPV and BMPV (Booster Mirror PV) systems that are superior to the conventional glass mirrors technology being currently used which is heavy, expensive and highly breakable.

Khurram Khan Nawabs other patents in the filed of green energy are:

- Alubond PV Booster Mirror.

- Receiver Tube ' Helios"

- Solar PV Plat Form.

- Solar Hydro electric Power system.

- PBB Green power system.

|

|

| |

|

| ASCM Advantages: |

| |

- Highly durable exterior grade core.

- Features phenomenal flatness

- Low maintenance.

- Mirror - Hydrophilic Principle (Self Cleaning Property)

- Easier handling, packaging and shipping

- Concentration full range UV, visible, NIR and IR (380 µm to 2400 µm)

|

- Light weight

- Retains its shape

- Mirror are mass produced

- Unbreakable Mirrors

|

|

|

|

| |

COST COMPARISON |

|

| |

|

|

| |

| CONVENTIONAL MIRROR SYSTEM |

|

MULK ENPAR RENEWABLE ENERGY SYSTEM |

| COST 4 TO 5 MILLION USD PER MW |

COST 3 to 3.5 MILLION USD PER MW |

|

|

|

| |

|

|

| |

MULK ENPAR RENEWABLE ENERGY KEY ADVANTAGES |

|

| |

|

|

| |

| CONVENTIONAL MIRROR SYSTEM |

|

MULK ENPAR RENEWABLE ENERGY SYSTEM |

| REFLECTOR PANEL HEAVY MIRRORS - 10 KG / M2 |

REFLECTOR PANEL LIGHT METAL MIRRORS – 3 KG / M2 |

| |

|

|

Difficult to retain parabolic shape |

|

|

Requires extensive support frame |

| |

| |

| |

| |

| |

|

|

| |

|

|

ASCM retains reflectivity (90-95%) and parabolic shape over a period of 20 years |

| |

|

|

Simple substrucutre support frame required |

| |

|

|

Savings of 200% in weight, substrantial savings in cost and higher efficiency |

| |

|

| |

|

|

|

|

| |

|

|

| |

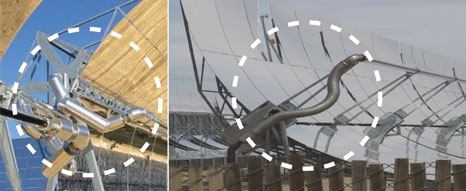

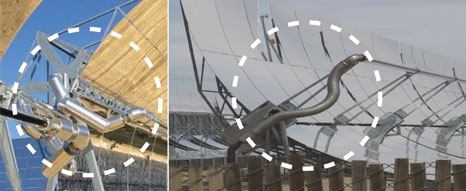

SUB FRAME, HYDRAULICS & HEIGHT |

|

| |

|

|

| |

| CONVENTIONAL MIRROR SYSTEM |

|

MULK ENPAR RENEWABLE ENERGY SYSTEM |

| HEAVY SPACE FRAME |

LIGHT WEIGHT SUB FRAME |

| HYDRAULICS REQUIRED |

HYDRAULICS NOT REQUIRED |

| NEED HEIGHT DUE TO HYDRAULICS |

LOW HEIGHT |

|

|

|

|

| |

|

|

| |

SOLAR RECEIVER TUBE & SWIVEL JOINTS |

|

| |

|

|

| |

| CONVENTIONAL MIRROR SYSTEM |

|

MULK ENPAR RENEWABLE ENERGY SYSTEM |

| SOLAR RECEIVER TUBE MOVING WITH SWIVEL JOINTS |

SOLAR RECEIVER TUBE FIXED WITHOUT SWIVEL JOINTS |

| SWIVEL JOINTS TWO FOR EVERY TROUGH |

SWIVEL JOINTS NOT NEEDED |

| |

|

|

Solar receiver tube placed high |

| |

|

Entire trough including the solar receiver is rotated using complex hydraulics. |

| |

|

This requires thousands of expensive swivel joints which require high maintenance. |

| |

|

|

| |

|

|

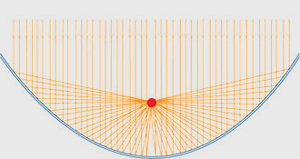

Solar receiver tube is fixed at the bed of the concave |

| |

|

|

A row of 9 troughs can be moved using a small motor of 0.33 HP / 246 Watts |

| |

|

|

System is capable of reaching temperatures over 400°c and a steam pressure of over 60 bar. |

| |

|

|

|

|

|

| |

|

|

| |

ROTATION SYSTEM & TRACKING SYSTEM |

|

| |

|

|

| |

| CONVENTIONAL MIRROR SYSTEM |

|

MULK ENPAR RENEWABLE ENERGY SYSTEM |

| TRACKS FROM BELOW USING HYDRAULICS & HEAVY MOTORS |

USES ARCHIMEDES PRINCIPLE. |

| LARGE MOTOR REQUIRED TO MOVE STANDARD TROUGHS. |

SUB ARRAY OF 9 TROUGHS MOVED USING A SMALL MOTOR. |

|

|

| |

|

|

| |

Archimedes said “ Give me lever and a place to stand and I will move the world ” |

|

| |

Mulk Enpar R.E uses the Archemedes lever principle that anything that can be moved from above will need less torque. |

|

| |

|

|

| |

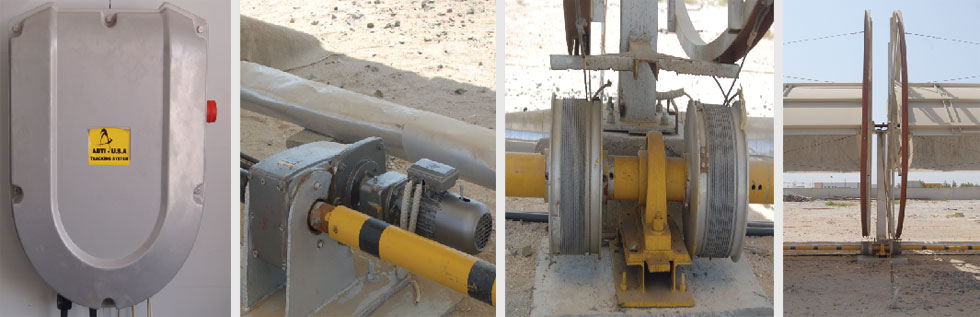

| ABTI Tracking Circuit |

Gear Motor |

Drum, Pipe & cable |

Tracking Big Wheel |

|

|

| |

|

|

| |

INSTALLATION TIME |

|

| |

|

|

| |

| CONVENTIONAL MIRROR SYSTEM |

|

MULK ENPAR RENEWABLE ENERGY SYSTEM |

| ON SITE INSTALLATION TIME 16 TO 18 MONTHS PER MW |

ON SITE INSTALLATION TIME 12 MONTHS |

|

|

| |

The Mulk Enpar Renewable Energy Solar system can be preassembled at site and brought to site for installation. |

|

| |

|

|

| |

OTHER KEY ADVANTAGES |

|

| |

|

|

| |

| CONVENTIONAL MIRROR SYSTEM |

|

MULK ENPAR RENEWABLE ENERGY SYSTEM |

| LAND REQUIRED 3.5 to 4 ACRES / MW. |

DUE TO LOW HEIGHT & REDUCED SHADOW EFFECT

LAND REQUIRED 3 ACRE / MW |

| SPACE BETWEEN TROUGHS LARGE SPACE DUE TO

HIGHER HEIGHT |

SPACE BETWEEN TROUGHS LOW SPACE DUE TO

LOW HEIGHT |

| EXTERIOR WARRANTY 15 TO 20 YEARS |

EXTERIOR WARRANTY 25 YEARS |

|

|

| |

|

|

| |

COLLECTOR EFFICIENCY - MULK ENPAR RENEWABLE ENERGY VS STANDARD TROUGH |

|

| |

|

|

| |

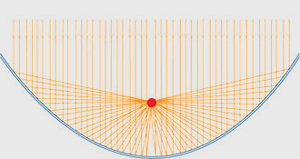

The ray-tracing program Mulk Renewable Energyp.exe calculates the trajectories of the sun’s rays and the radiated rays from all the surfaces in the collector. The table above gives collector efficiency between Mulk Renewable Energy Trough and a standard trough, showing Mulk Renewable Energy is less sensitive to tracking errors than standard troughs. |

|

| |

DEGREES OFF CENTER ( DOC ) |

MULK R.E ( % ) |

STANDARD TROUGH ( % ) |

0 |

81.2 |

81.1 |

0.5 |

81.2 |

80.2 |

0.7 |

80.2 |

76.2 |

0.8 |

75.1 |

59.2 |

1 |

64.5 |

29 |

1.2 |

53 |

0 |

1.5 |

38.4 |

0 |

|

|

|

|

|

| |

|

|

| |

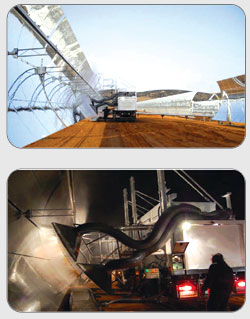

MAINTENANCE AND CLEANING |

|

| |

|

|

| |

|

|

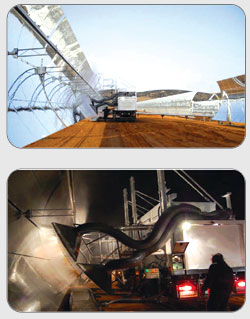

- Regular and constant velocity

- Adjustable water pressure & flow rate

- Mechanical Cleaning with Rotation brush

- Water recycling ( Recovery Filtration and Reuse)

- Drying with high flow rate of air

- Remote Radio controlled panel

- CCTV cameras

- Ability to work in adverse conditions

- Low water consumption

- Cleaning of the top and bottom of the parabola same time

- Simultaneous cleaning of receiver tube

- Elimination of Swivel joints greatly reduces the complexity of Maintenance operations and breakdown time.

|

| |

|

|

|

|